Home

Home

Product center

Product center

Wheel components

Wheel components

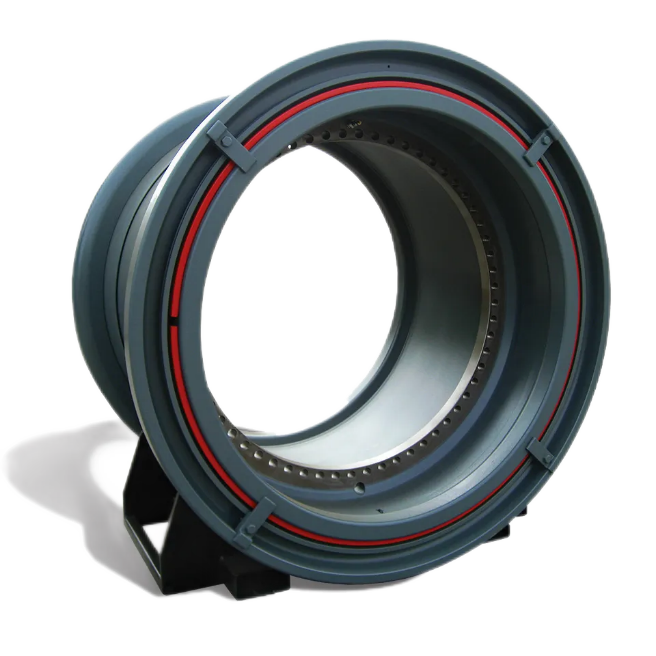

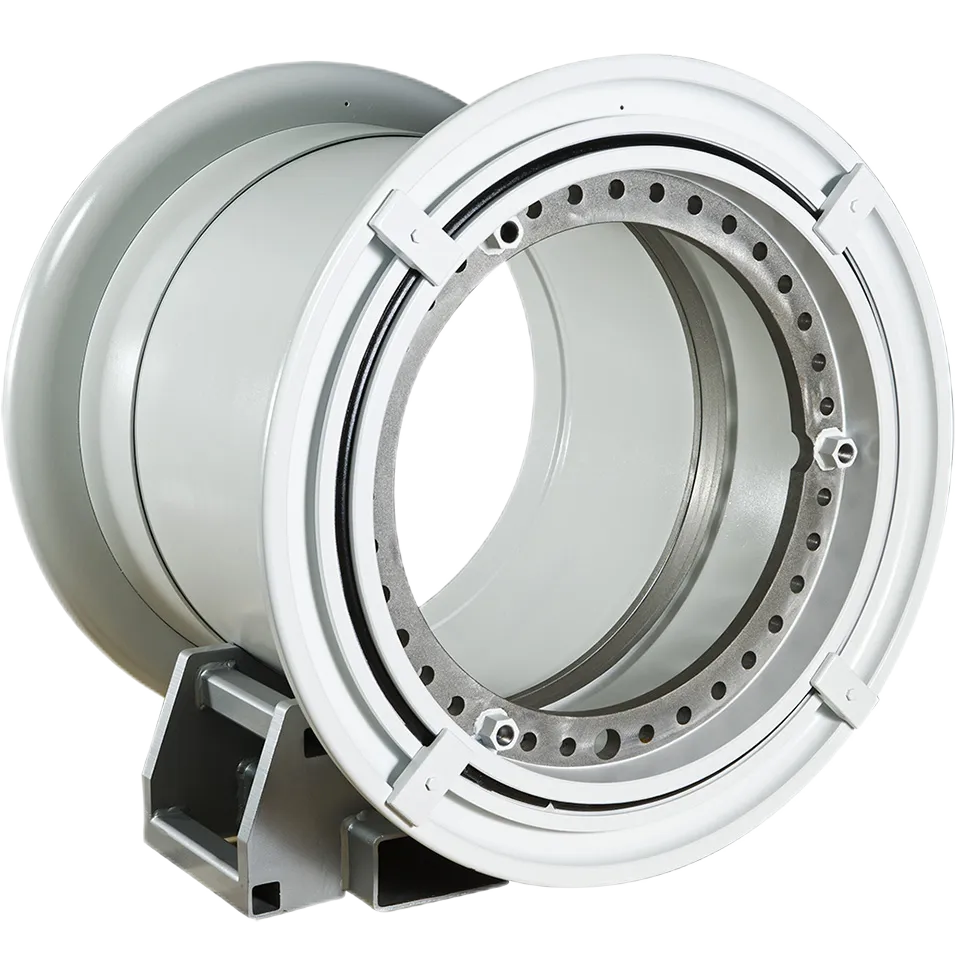

The unique design of the Taper Secure Radial (TSR) Series uses a taper concept to secure all components in place. Absolute stability of components and the tire is achieved as movement between parts is eliminated. When the tire is inflated, the rim parts lock into their tapered landing areas.

The key benefit of the TSR design is absolute tire support. The wheel flanges DO NOT MOVE on the wheel base. The tire is anchored with complete stability and no air pressure is lost. As well as extending tire life, the life of rim components is increased as there is no wearing or fatiguing of the parts from component movement.

Product Specifications

TSR's unique design uses a tapered concept to hold everything in place. First produced in 1992, the TSR provides absolute stability for the tire and wheel assembly.

Available in wheel sizes from 29″ – 63″

Available in wheel sizes from 29″ – 63″

Available in standard 5-piece assembly and as Double Gutter Service (DGS) / Integral Gutter Lock Ring (IGLR) assemblies

Available in standard 5-piece assembly and as Double Gutter Service (DGS) / Integral Gutter Lock Ring (IGLR) assemblies

Each TSR wheel is custom manufactured for precise fitment to the specified machine

Each TSR wheel is custom manufactured for precise fitment to the specified machine

Related Features

Unique taper design secures ALL components in place.

Increased material in critical mass areas eliminates component movement and flexing

True roundness of the machined taper design virtually eliminates bead seat band and lock ring damage

Less wear and fatigue equals increased safety

Fully machined bead seating areas allow for easier mounting and demounting of tires

Tire beads are secure and stable.

Air loss is eliminated

Helps tires run cooler and maintain even air pressure

Increased tire life

Extended product life.

TSR wheels are designed to last the life of the equipment they are fitted to

Wear and fatigue to all rim components is reduced with the taper concept

TSR lock rings are RED.

Easily identifiable in service

Only compatible with TSR components