Home

Home

Product center

Product center

Wheel components

Wheel components

Product Specifications

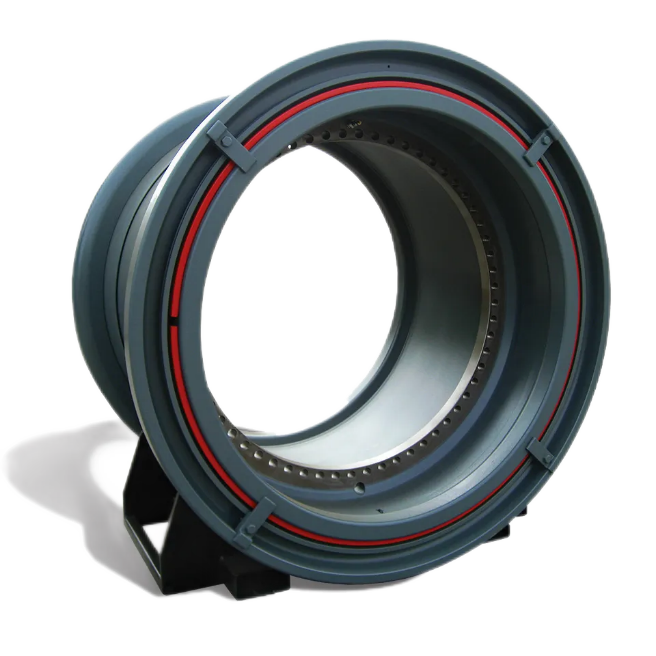

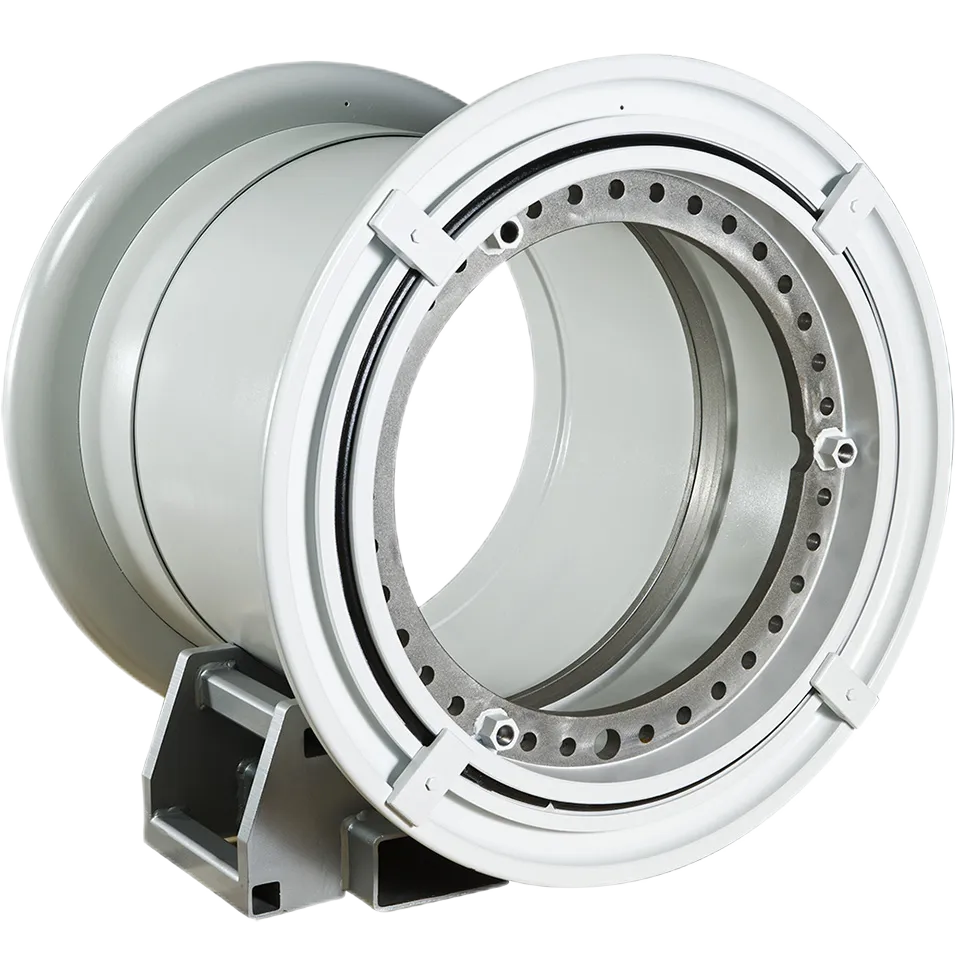

RIMEX introduced the Machined Extreme Service (MES) Series of wheels and rims to address the serious impact radial tires had on rim performance. The increased flexibility in radial tire sidewalls caused movement in the bead seat area. Recognizing the problem, RIMEX pioneered the first wheel produced using fully machined sections—the MES.

Available in wheel sizes from 20″ – 63″

Available in wheel sizes from 20″ – 63″

Available in standard 5-piece assembly and as Double Gutter Service (DGS) / Integral Gutter Lock Ring (IGLR) assemblies

Available in standard 5-piece assembly and as Double Gutter Service (DGS) / Integral Gutter Lock Ring (IGLR) assemblies

Each MES wheel is custom manufactured for precise fitment to the specified machine

Each MES wheel is custom manufactured for precise fitment to the specified machine

Related Features

Fully machined and truly round in critical areas

Improved rim component and tire bead fit

Reduced wear and fatigue of rim components

Longer component life achieved

Knurless back section and bead seat bands have 75% more contact area than comparable rim products.

Air loss is eliminated due to tire slippage

Reduced tire slippage as beads are able to seat properly

Bead damage from tire slippage eliminated

Increased component thickness

Reliability and safety achieved

More robust product over industry standard products

Longer component life

Compatibility

fully interchangeable with industry standard products in most applications.