Wheels And Mesh

-

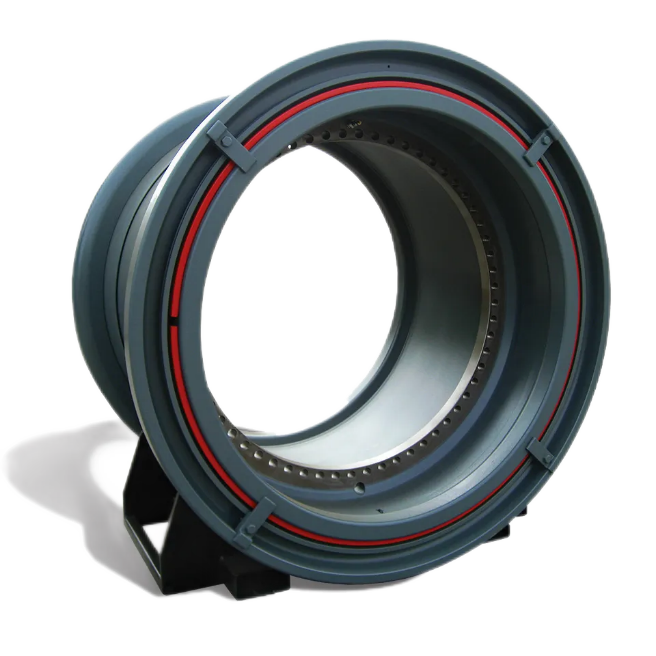

TSR WHEELS

The unique design of the Taper Secure Radial (TSR) Series uses a taper concept to secure all components in place. Absolute stability of components and the tire is achieved as movement between parts is eliminated. When the tire is inflated, the rim parts lock into their tapered landing areas.

The key benefit of the TSR design is absolute tire support. The wheel flanges DO NOT MOVE on the wheel base. The tire is anchored with complete stability and no air pressure is lost. As well as extending tire life, the life of rim components is increased as there is no wearing or fatiguing of the parts from component movement.

-

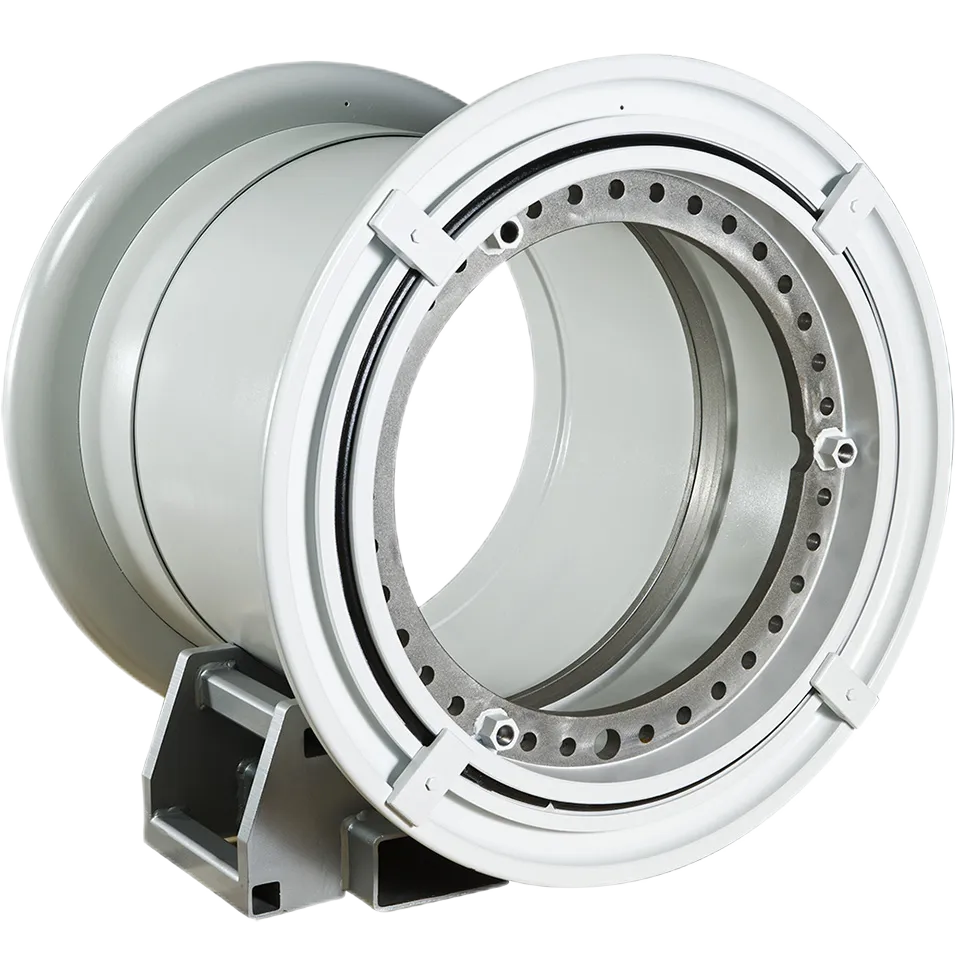

MES WHEELSWHEELSRIMEX introduced the Machined Extreme Service (MES) Series of wheels and rims to address the serious impact radial tires had on rim performance. The increased flexibility in radial tire sidewalls caused movement in the bead seat area. Recognizing the problem, RIMEX pioneered the first wheel produced using fully machined sections—the MES. Since their introduction in 1988 MES wheels remain a popular choice, and, in addition to the standard 5 piece assembly, they are available with DGS or IGLR components for faster tire changes without removing the outer rim.

-

DGS WHEELS

The revolutionary Double Gutter Service (DGS) Series is a RIMEX TSR wheel/rim assembly with two bead bands, two side rings, one two-piece lock ring and one standard lock ring. The DGS was developed as a position-sensitive outer dual so the inside tire could be easily mounted/demounted without removing the outer wheel/rim base. It is designed with safety and time savings in mind — tire changes are completed in a fraction of the time. RIMEX DGS wheels can be installed to haul truck outer dual positions without upgrading the inner dual wheels. Now the inner dual tires can be changed without removing the outer dual.

-

IGLR WHEELS

IGLR wheels are designed for front steering and interior dual positions.

When IGLR wheels are installed on all four positions of the loader wheel, tire changes are quick and easy; allowing stubborn tire beads to be tackled as time permits.

IGLR components can be pre-installed using RIMEX pre-installed brackets, significantly reducing tire repair downtime.

-

MST WHEELS

RIMEX developed Machined Secure Taper (MST) rims in response to industry demand for a ‘wedge’ style rim to replace standard OEM 57″ and 63″ rims. MST wheels and rims are fully machined, longer life products designed to withstand the harshest of conditions.

-

EMH LOCK RING

The EMH lock ring is designed to meet the need for a stronger and safer rim to suit the high pressures and increased loads of many earthmoving and industrial applications without compromising safety. This product can be produced utilizing MES and TSR components.

By engineering a thicker, stronger lock ring RIMEX is able to offer improved strength and capacity in a RIMEX wheel with only minor design adjustments. The EMH lock ring is utilized with both MES and TSR series wheels.

With the MES Series wheel, the only difference in the rim design is the lock ring and lock ring groove in the rim. The MES Series wheel assembly remains fully compatible with standard side rings and bead seat bands. An EMH style wheel allows for increased pressures and stresses without sacrificing safety concerns; as standard wheels are not safely rated for high air pressures or loads. Sizes available are 24” through 49” rim diameters.